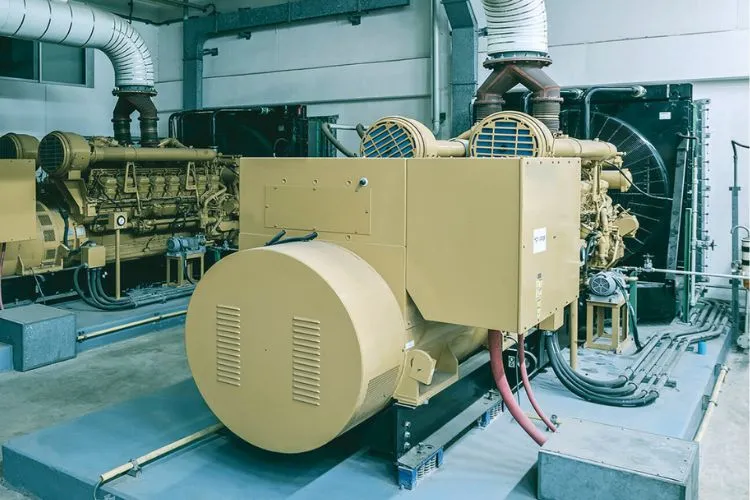

Diesel generators stand as reliable power sources for various applications, from serving emergency backup needs to providing primary power in areas lacking access to the electrical grid.

Their ability to deliver power reliably makes understanding how to extend their lifespan vital.

This article on how to expand life span of your diesel generator delves into practical strategies to ensure your diesel generator remains operational for years.

How to Expand Life Span of Your Diesel Generator?

The lifespan of diesel generators varies, influenced by several factors including maintenance, usage, and environmental conditions.

Typically, a well-maintained diesel generator can last between 20,000 to 30,000 hours of operation. This range highlights the importance of proper care and maintenance in extending a generator’s service life.

Regular Maintenance Schedule

Adhering to a regular maintenance schedule forms the cornerstone of prolonging your diesel generator’s lifespan. Such a schedule should encompass:

Oil Changes: Regular oil changes ensure your generator’s engine runs smoothly. Replace the oil and oil filter according to the manufacturer’s guidance, usually every 500 hours of operation. This prevents the build-up of contaminants that can wear down engine parts.

Air Filter Maintenance: A clean air filter is crucial for efficient operation. Check the air filter periodically and replace it as needed, typically every 500 hours. This keeps dust and debris from entering the engine, which could decrease performance and lifespan.

Fuel Management: Diesel quality directly impacts generator performance. Use clean, high-quality diesel and avoid leaving fuel in the tank for extended periods to prevent degradation and contamination.

Cooling System Checks: The cooling system helps maintain optimal operating temperatures. Ensure the coolant level is within the recommended range and inspect the system for leaks regularly.

Optimal Operation Practices

Operating your generator within its recommended load levels is essential. Consistently running it at too low or too high a capacity can lead to “wet stacking” or excessive wear.

Furthermore, adhere to proper startup and shutdown procedures to reduce stress on the generator’s components.

Storage Solutions

Proper storage during downtime is essential to prevent damage. Store your generator in a dry, well-ventilated area, and consider the use of desiccants or heaters in humid or cold environments, respectively, to ward off corrosion and mechanical issues.

Monitoring and Replacing Parts

Regular inspection helps identify wear and tear before they lead to significant issues. Key components such as the battery, fuel injectors, and belt should be checked frequently and replaced as necessary with genuine parts to ensure reliability and performance.

Professional Servicing and Repairs

While routine maintenance can often be completed by the owner, certain tasks require professional expertise.

Regular professional servicing ensures thorough inspection, maintenance, and, if needed, repair of your diesel generator.

Look out for signs like unusual noises, difficulty starting, or inconsistent power output as indicators that professional service may be needed.

Innovations in Generator Care

Embrace technological advancements designed for generator maintenance. Smart monitoring systems can track operation in real-time, alerting you to potential issues before they become serious problems.

Integrating these technologies can make maintaining your generator simpler and more effective.

Energy Efficiency Practices

Optimizing the energy efficiency of a diesel generator is a crucial practice for extending its lifespan, reducing operational costs, and minimizing environmental impact.

At the heart of efficiency is ensuring the generator size closely matches the load demand. An oversized generator runs underloaded, leading to inefficient combustion and “wet stacking,” which can cause significant wear.

Conversely, a generator running near its maximum capacity can overheat, stressing its components. Finding the right balance not only conserves fuel but also prevents unnecessary strain on the generator’s engine and parts.

Furthermore, pairing your diesel generator with energy-efficient appliances can dramatically reduce the overall power load.

These appliances consume less electricity, decreasing the generator’s workload and fuel consumption.

Implementing these practices not only extends the useful life of your diesel generator but also contributes to more sustainable operation by lowering fuel use and reducing emissions.

Environmental Considerations

Environmental factors such as temperature extremes, humidity, and exposure to dirt and dust significantly impact the performance and lifespan of diesel generators.

High temperatures can lead to overheating, while extremely low temperatures may cause starting difficulties and increased wear during cold starts.

Humidity can contribute to corrosion and electrical component failure, and dirt and dust accumulation can clog air filters and cooling fins, hindering efficient operation.

To mitigate these environmental impacts, proper installation and housing of diesel generators are essential. Install generators in well-ventilated areas that remain dry and are protected from direct exposure to the elements.

For areas prone to high temperatures, ensure adequate cooling mechanisms are in place. In colder climates, consider using engine block heaters to ease starting in low temperatures.

Implement dust and dirt management strategies, such as regular cleaning schedules and protective enclosures, to keep the generator clean and maintain optimal performance levels.

Through these measures, you can safeguard your diesel generator against adverse environmental conditions, ensuring its reliability and extending its service life.

Frequently Asked Questions (FAQs)

What is the average lifespan of a diesel generator?

With proper maintenance, a diesel generator can last between 20,000 to 30,000 hours of operation.

How often should a diesel generator be serviced?

Professional servicing should occur at least annually, though specific intervals depend on the manufacturer’s recommendations and the generator’s usage patterns.

Can I perform maintenance tasks on my diesel generator myself?

Many maintenance tasks, such as oil changes and air filter replacements, can be done personally if you follow the manufacturer’s guidelines. However, complex issues should be handled by professionals.

What are common signs that my diesel generator needs repair?

Signs include difficulty starting, unusual noises, and inconsistent power output, indicating it’s time to consult a professional.

Conclusion:

In summary, extending the lifespan of a diesel generator boils down to regular maintenance, proper operation, and timely professional servicing.

By following the outlined strategies, you can not only ensure your generator remains reliable but also maximize your investment.

Prioritize your diesel generator’s care to enjoy uninterrupted power when you need it most.