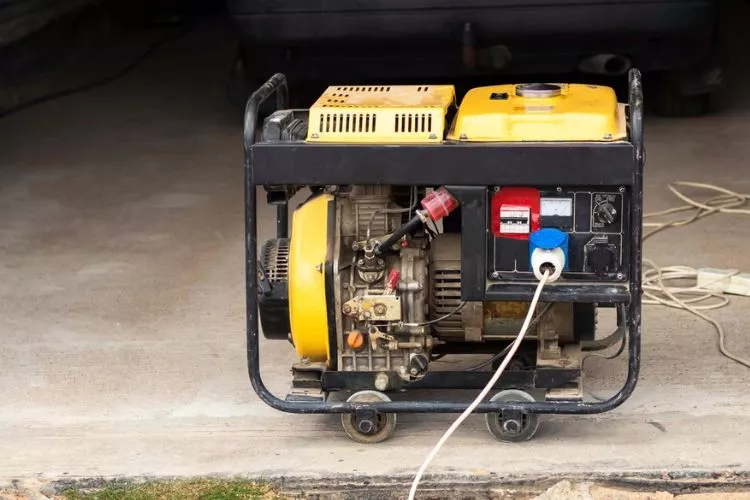

A generator is a reliable source of power during emergencies or in areas without electricity.

Ensuring its proper maintenance is crucial for optimal performance and longevity.

One essential maintenance task is draining old gas from the generator’s tank.

In this guide, we will take you through the step-by-step process of how to drain old gas from a generator, providing helpful tips and insights along the way.

how to drain old gas from a generator? A Stepwise Guide

When a generator sits unused for an extended period, the gas inside can begin to degrade.

Old gas can lead to poor engine performance, blockages in the fuel system, and even engine damage.

Draining old gas from your generator is essential to maintain its efficiency and avoid potential issues down the line.

Proper Preparation

Before starting the process, choose a well-ventilated area that is free from any sources of ignition. Gather the necessary materials, including safety goggles, gloves, a drain pan, a wrench, and fresh gasoline.

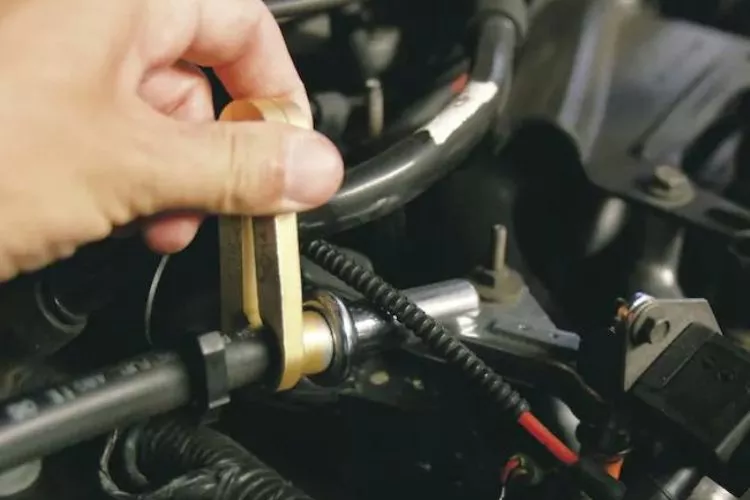

Disconnecting the Fuel Line

The first step to drain old gas is to turn off the fuel valve. Locate the fuel valve on your generator and switch it to the “Off” position.

Once the fuel valve is closed, detach the fuel line from the generator by removing the clamp or screw that holds it in place.

Draining Gas from the Tank

- Find the drain bolt: Locate the drain bolt underneath the generator’s tank. Refer to your generator’s manual for specific instructions on locating the drain bolt.

- Position the drain pan: Place the drain pan underneath the drain bolt to catch the old gas.

- Loosen the drain bolt: Use a wrench to loosen the drain bolt in a counterclockwise direction. Be cautious as the old gas may be under pressure.

- Drain the old gas from the tank: Allow the old gas to flow into the drain pan until the tank is completely empty. Ensure that you dispose of the old gas properly according to local regulations.

Cleaning the Carburetor

Over time, the carburetor can become clogged with impurities from old gas. Cleaning the carburetor will improve the generator’s performance.

- Remove the carburetor: Follow your generator’s manual to locate and remove the carburetor from the generator.

- Demount the bowl: Carefully remove the carburetor bowl, which is often secured with screws. Be mindful of any gaskets or O-rings that may be present.

- Clean the carburetor bowl: Use a carburetor cleaner and a soft brush or cloth to remove any built-up debris or varnish from the bowl. Ensure that all the tiny holes and channels are clear.

- Replace the carburetor: Once the carburetor is cleaned, reassemble it following the reverse steps to ensure it is correctly positioned and securely fastened.

Refilling the Generator

After successfully draining the old gas and cleaning the carburetor, it is time to refill the generator with fresh gasoline.

- Choose the right fuel: Check your generator’s manual for the recommended type and octane rating of gasoline.

- Fill the tank: Slowly pour fresh gasoline into the generator’s tank, avoiding overfilling.

- Start the generator: Once the tank is filled, follow your generator’s startup procedure to get it running smoothly.

Importance of Draining Old Gas from a Generator

Draining old gas from a generator is crucial to maintaining its efficiency and avoiding potential issues. Let’s delve into the importance of this maintenance task in more detail.

Prevents Poor Engine Performance:

When gasoline sits unused for a long time, it can break down and become less effective as a fuel source. This degraded gas can result in poor engine performance, causing the generator to struggle to operate at its full capacity.

As a result, the generator may not provide the required power output or may fail to start altogether. Draining old gas ensures that fresh, high-quality fuel can be used, maximizing the generator’s performance.

Avoids Fuel System Blockages:

Over time, old gas can leave behind deposits and contaminants that accumulate in the fuel system. These deposits may clog fuel filters, fuel lines, or the carburetor, obstructing the flow of fuel to the engine.

A blocked fuel system can disrupt the combustion process, leading to reduced power output and potentially damaging the engine. By draining old gas and cleaning the fuel system, you can prevent blockages and maintain proper fuel flow.

Protects against Engine Damage:

Using degraded gas can have detrimental effects on the generator’s engine. The impurities present in old gas, such as varnish or sediment, can build up in crucial engine components, including the carburetor, valves, pistons, and spark plugs.

This buildup can affect the engine’s performance, causing it to run inefficiently or even result in permanent damage.

Draining the old gas and cleaning the carburetor ensures that these harmful deposits are removed, reducing the risk of engine damage and extending the lifespan of the generator.

Improves Fuel Efficiency:

Old gas does not burn as efficiently as fresh gasoline. As a result, the generator may consume more fuel to generate the same amount of power, leading to decreased fuel efficiency.

By draining old gas and replacing it with fresh fuel, you can optimize the generator’s fuel consumption, allowing it to operate more efficiently and potentially saving you money on fuel costs in the long run.

Promotes Overall Generator Longevity:

Regularly maintaining your generator, including draining old gas, is essential for its longevity. By taking care of your generator and ensuring that it operates with clean fuel, you minimize the risk of premature wear and tear on the engine components.

This, in turn, extends the lifespan of the generator and reduces the likelihood of unexpected breakdowns or costly repairs.

In conclusion, draining old gas from your generator is a crucial maintenance task that should not be overlooked.

It helps maintain the generator’s efficiency, prevents fuel system blockages, protects against engine damage, improves fuel efficiency, and promotes overall longevity.

By regularly draining old gas and using fresh, high-quality fuel, you can ensure that your generator is always ready to provide reliable power when you need it most.

Frequently Asked Questions (fAQs)

Is it necessary to drain old gas from a generator?

Yes, draining old gas is necessary to maintain the generator’s performance and avoid potential issues.

What are the consequences of not draining old gas from a generator?

Not draining old gas can lead to poor engine performance, fuel system blockages, and potential engine damage.

Can I use a stabilizer instead of draining old gas from a generator?

While a stabilizer can help prolong the life of a generator’s fuel, it is still recommended to drain old gas to ensure optimal performance.

How often should I drain old gas from my generator?

It is generally recommended to drain old gas if the generator has been sitting unused for more than one month.

Should I use a professional to drain old gas from a generator?

If you’re uncomfortable performing the task yourself, it is advisable to seek the assistance of a professional to avoid any mistakes or damage to the generator.

Tips for Maintaining Your Generator Beyond Draining Old Gas

While draining old gas is a critical step in maintaining your generator, it’s not the only task that ensures its longevity and efficiency. Regular upkeep of your generator will help keep it running smoothly and minimize the risk of costly repairs.

Regular Oil Changes

Just like any other engine, your generator requires regular oil changes to ensure that the moving parts are properly lubricated. Old, degraded oil can cause excessive wear on the engine components, leading to reduced performance or even engine failure.

Refer to your generator’s manual for the recommended oil change interval and always use the manufacturer’s suggested oil type.

It’s a good idea to check the oil level before each use and top it off if necessary. Make sure the oil is clean and free of debris, as contaminants can also contribute to engine damage.

Air Filter Maintenance

The air filter in your generator plays a vital role in ensuring that the engine receives clean air for combustion. A clogged or dirty air filter can reduce airflow, leading to inefficient fuel combustion and increased wear on the engine.

Inspect the air filter regularly, especially if you use the generator in dusty or dirty environments. Clean or replace the air filter as needed to maintain optimal airflow.

Battery Care

If your generator has a battery, it’s important to check its charge and condition regularly. Over time, batteries can lose their charge or degrade, which may prevent the generator from starting when needed.

If the battery is removable, store it in a cool, dry place during long periods of non-use, and check the battery’s condition periodically. Some generators also come with automatic charging systems, so ensure they are functioning properly.

Inspecting the Fuel System

In addition to draining old gas, it’s wise to periodically inspect the entire fuel system. Look for any cracks, leaks, or signs of corrosion in the fuel lines.

A compromised fuel line can cause fuel to leak, posing a fire risk or leading to inefficient fuel delivery. Replacing worn-out fuel lines promptly will keep your generator running at peak performance.

By regularly performing these maintenance tasks, you can maximize your generator’s lifespan and ensure it’s ready to deliver reliable power when you need it most.

Conclusion:

Proper maintenance of your generator, including draining old gas, is crucial for optimal performance and longevity.

By following the step-by-step process we’ve outlined, you can ensure that your generator is ready to power your home or equipment reliably.

Remember to schedule regular maintenance tasks to keep your generator in top shape.