What is Generator Power Factor? It’s like a score that shows how well a generator uses electricity. Imagine filling a cup with water. If you fill it perfectly without spilling, that’s like having a high score. But if it spills, that’s not so good.

Generator Power Factor measures this in the world of generators, aiming for less spillage and more efficiency. Understanding it helps us use energy better, saving money and resources.

What is Generator Power Factor?

At its core, the generator power factor (GPF) describes the efficiency with which a generator uses electricity to produce useful power. It is essentially a measure of how effectively electrical power is converted into useful work output, the degree to which electrical power is utilized effectively.

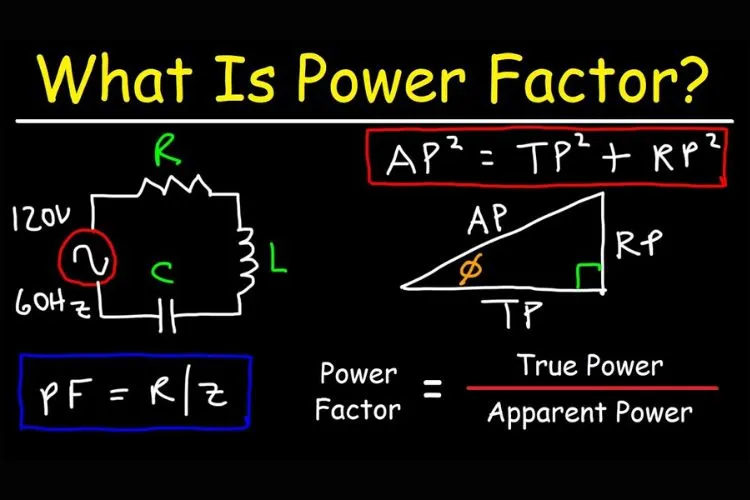

But to fully grasp this, we must differentiate between real power (measured in kilowatts, kW), apparent power (measured in kilovolt-amperes, kVA), and reactive power (measured in kilovolt-amperes reactive, kVAR).

Real power is the capacity of the circuit for performing work in a particular time. Apparent power, on the other hand, is the product of the current and voltage in the circuit, regardless of whether the power actually does useful work.

Lastly, reactive power is the portion of electricity that establishes and sustains the electromagnetic fields but does no productive work. Power factor, therefore, in the context of generators, measures the ratio of real power doing work to the apparent power in the circuit, expressed as a percentage or a decimal between 0 and 1.

Why is Generator Power Factor Important?

The significance of GPF cannot be overstated. A high power factor signifies efficient utilization of electrical power, whereas a low power factor indicates poor efficiency and greater losses.

This efficiency affects not only operational costs but also the sizing and capacity of generators. A generator with a high power factor is capable of providing more power for the same amount of fuel, leading to cost savings on fuel consumption and reducing carbon footprint.

Moreover, understanding and optimizing GPF can prevent over-sizing or under-sizing of generators, ensuring that equipment is neither overburdened nor wastefully idle.

How to Calculate Generator Power Factor

Calculating the GPF involves dividing the kW (real power) by the kVA (apparent power). Consider a generator producing 800 kW (real power) and working at an apparent power of 1000 kVA.

The power factor then is 800 kW / 1000 kVA = 0.8 (or 80%). This calculation reveals the efficiency of the generator in converting electric power into useful work.

Factors Affecting Generator Power Factor

Understanding what influences GPF is crucial for optimization. Load types play a significant role; resistive loads (like heaters) have power factors closer to 1, indicating high efficiency, while inductive loads (like motors and transformers) can significantly lower the power factor due to their reactive power consumption.

The interactions between the generator and the loads it serves also impact the power factor, underscoring the importance of matching load types to generator capabilities.

Optimizing Generator Power Factor

Enhancing a generator’s power factor can lead to substantial economic and operational benefits. This can be achieved through various means, such as the use of capacitors or power factor correction devices, which reduce the phase difference between voltage and current, thereby improving power factor.

Additionally, regular maintenance to ensure optimal performance and replacing or adjusting equipment to better match load requirements can make a significant difference.

Case Studies/Real-life Applications

Real-world applications vividly illustrate the significance of GPF optimization. In industrial settings, for example, upgrading to high-efficiency motors and incorporating power factor correction units have led to reductions in energy consumption and costs.

Similarly, data centers have significantly benefited from power factor optimization, achieving not only cost savings but also enhanced stability and reduced thermal stress on equipment.

Impacts of Generator Power Factor on Electrical Infrastructure

The efficiency of electrical systems is not only about saving energy or reducing bills; it has a profound impact on the very infrastructure that generates and distributes power.

A low power factor often comes with a silent alarm—one that signals the overloading of generators and electrical infrastructure, heralding increased maintenance costs, and in severe cases, system failures.

When the power factor dips, it is a sign that the electrical system is not being used to its fullest potential. But what does this entail for the physical components that make up this system?

Under a low power factor, electrical currents increase to deliver the same amount of useful power, where the excess energy is wasted as heat. This heat is the primary culprit behind the stress on infrastructure.

Increased Current Flow and Overloading:

A generator feeding power into a system with a low power factor must work harder, i.e., push more current through the system for the same amount of usable power. For instance, if a system operating at a power factor of 0.8 could require a 25% higher current to perform the same work as a system running at a power factor of 1.0.

These higher currents lead to potential overloading of the generator and distribution equipment such as transformers and conductors. This elevated current can push these components beyond their designed capacity, leading to overheating and reduced lifespan.

Degradation of Equipment:

Continuous operation under conditions of low power factor can significantly degrade the condition of electrical equipment. Not only do transformers and cable lines suffer, but the protective devices and switches also endure more strain due to the higher current required.

Over time, insulation may break down, connections may loosen or oxidize, and the general deterioration of the generator and associated devices can hasten the move towards failure.

Increased Maintenance and Downtime:

Naturally, as equipment degrades or fails, maintenance activity ramps up. More frequent repairs or replacements become the norm, not just as a means of restoring operations but as a preventative measure against unexpected outages.

This means increased direct costs for parts and labor, and potentially significant indirect costs from downtime. Manufacturing lines may halt, data centers may experience interruptions, or heating and cooling systems may become non-operational—each of these scenarios costs money and time and may affect service delivery or product quality.

Higher Operating Costs:

There is also an economic dimension to falling power factors. Utilities often charge penalties for low power factors or offer incentives for high ones because it costs them more to deliver electricity inefficiently.

This leads to increased operating costs for businesses, which must contend with these utility charges on top of the increased costs for maintenance and component replacements.

Risk of System Failures:

In the worst-case scenario, the ever-present risk of outright system failure looms. An overloaded transformer could fail catastrophically, cutting power to an entire production line or building.

Cable fires are also a risk, with the potential for significant property damage or even injury to personnel. Circuit breakers may trip more frequently, causing sporadic power losses.

In conclusion, the repercussions of a low generator power factor stretch beyond superficial inefficiency—they dig deep into the lifelines of electrical infrastructure.

By thoroughly understanding and proactively managing power factor, industries can save considerably on maintenance costs, enhance the longevity of their electrical systems, and most importantly, mitigate the risk of system failures that carry both financial and safety consequences.

You may also find useful: What is a CARB Compliant Generator?

Frequently Asked Questions (fAQs)

What is a good power factor for a generator?

A good power factor is generally considered to be between 0.95 and 1.0. However, achieving this may not always be practical or necessary, depending on specific operational requirements.

How does load type affect generator power factor?

Load type significantly influences GPF because different types of loads consume power differently. Resistive loads improve power factor, while inductive loads can lower it due to their reactive power usage.

Can generator power factor be too high?

While a higher power factor indicates more efficient power use, extremely high power factors (close to 1) can sometimes indicate under-loading of the generator, which can also be inefficient and lead to other issues.

How to adjust power factor on a generator?

Adjusting a generator’s power factor may involve adding power factor correction capacitors to the system, redesigning the system to better match the load, or upgrading equipment to more efficiently use power.

Conclusion:

The generator power factor stands as a pivotal measure in the quest for energy efficiency and operational excellence. Its understanding and optimization are essential for businesses aiming to reduce operational costs, extend equipment life, and contribute to environmental sustainability.

By investing time and resources into optimizing GPF, organizations can reap significant benefits, marking a step forward in achieving energy efficiency goals.